RESISTANCE TEMPERATURE DETECTOR

THE PRINCIPLE, TYPE, AND FEATURE OF RESISTANCE TEMPERATURE DETECTORS

- THE PRINCIPLE, TYPE, AND FEATURE OF RESISTANCE TEMPERATURE DETECTORS

- TYPES OF RTD

- FEATURE OF RTD

- LEAD WIRE CONFIGURATION OF RTD

THE PRINCIPLE, TYPE, AND FEATURE OF RESISTANCE TEMPERATURE DETECTORS

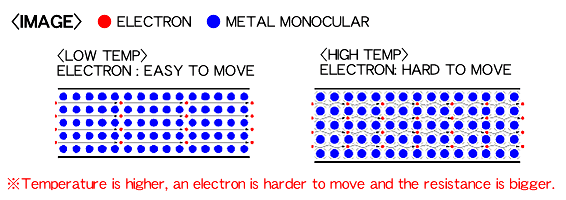

An RTD sensor exploits the theory that electric resistance value of a platinum wire or pattern is changed by a temperature change. In principle, any kind of metals has the characteristic. However,

Practically using the characteristic to accurate measurement, there are some conditions such as resistance value change versus temperature should be constant and interchangeable, temperature coefficient resistance should be large, and so on. Therefore, the applicable metals are limited from those conditions in practical field.

Practically using the characteristic to accurate measurement, there are some conditions such as resistance value change versus temperature should be constant and interchangeable, temperature coefficient resistance should be large, and so on. Therefore, the applicable metals are limited from those conditions in practical field.

Measurement principle is to measure a change of resistance value by applying electric current to an RTD element. (0.5mA to 2mA)

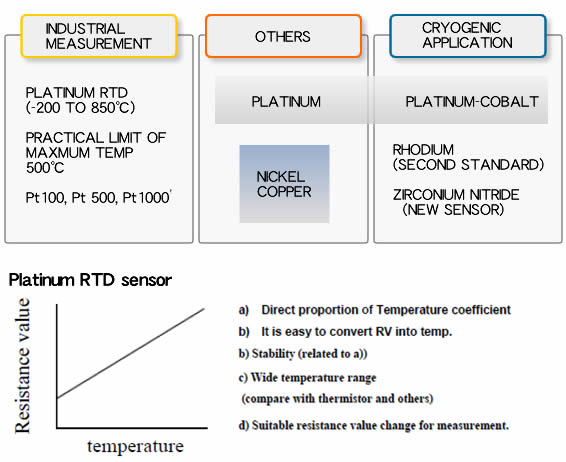

TYPES OF RTD

Main trend for industrial resistance temperature detector is platinum RTD due to physical stability and high applicable temperature.

There are the other RTDs such as Nickel, Platinum-cobalt, and so on.

There are the other RTDs such as Nickel, Platinum-cobalt, and so on.

FEATURE OF RTD

A platinum RTD probe has the features as follow comparing with a thermocouple probe.

- The platinum RTD probe has a big advantage on measuring temperature similar to room temperature because resistance value change versus temperature is large, and reference junctions that are necessary for thermocouple is not used for an RTD probe.

- The platinum RTD probe has high long term stability.

- The platinum RTD probe enables highly accurate measurement.

- Maximum temeperature for the platium RTD probe is lower than a thermocouple probe.

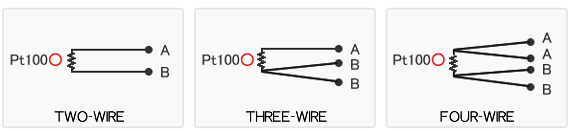

LEAD WIRE CONFIGURATION OF RTD

The general lead wire configuration for industrial RTD probes is three-wire configuration. There is also two-wire type. However, the resistance value on lead wire is added directly on a measurement, and the error is bigger than three-wire type. Three-wire configuration, which is widely applied for industrial applications, can offset the error and enable a precise measurement. In case more precise measurement requires, four-wire configuration is applied.