RESISTANCE TEMPERATURE DETECTOR

NOTIFICATION FOR CHOOSING PROPER SENSOR

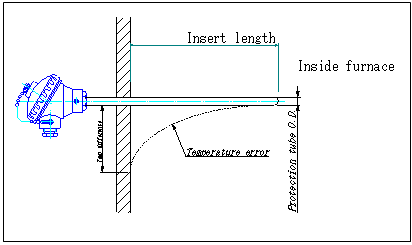

ERROR BY LACK OF INSERT LENGTH

A precise measurement is not possible unless the temperature of a measured object and a measuring junction for a thermocouple and an RTD element for an RTD become the same temperature. Generally, temperature goes down to outward the sensor by heat conduction because the measuring part is inserted a protection tube. A insert length is different by a different condition. The chart below shows necessary insert lengths by multiplying a outer diameter of protection tube.

NECESSARY INSERT LENGTH FOR PRECISE MEASUREMENT

| TYPE | STILL LIQUID | STILL ATMOSPHERE |

|---|---|---|

| RTD (MI sheath) | MORE THAN 10 TIMES | MORE THAN 15 TIMES |

| RTD (protection tube) | MORE THAN 10 TIMES | MORE THAN 15 TIMES |

| T/C (metal) | MORE THAN 15 TO 20 TIMES | |

| T/C (ceramic) | MORE THAN 15 TO 20 TIMES |

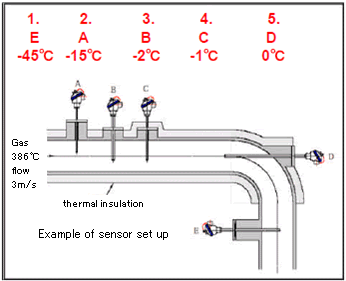

CASE STUDY FOR SENSOR SET UP

1. CASE E -45℃

Lack of the insert length, the volum of the boss is too large, and no thermal insulation on the pipe.

2. CASE A -15℃

Lack of the insert length, the volum of the boss is too large, and lack of thermal insulation on the pipe.

3. CASE B -2℃

Good boss installation, but no thermal insulation on the flange.

4. CASE C -1℃

The installation is good, but a little lack of insert length.

5. CASE D 0℃

The best way for the installation.

RESPONSE SPEED

It takes some time for an element and a measuring junction being the same temperature as an object. It is called “temporal error.” A smaller diameter responds faster, but mechanically weaker. It is important to choose a sensor by the purpose and necessity.

Please refer to each technical data for response time.

Please refer to each technical data for response time.